Seamus – Wood Turner and Sculptor

Seamus lives with his family near Slane in the Boyne Valley, close to the historic 5,000-year-old site of Newgrange.

See their workCeltic Shield Collection

He has a unique ability to recognize a beautiful object in a piece of wood and uses his skills to reveal the hidden and unique beauty.

See their workArtisan-Seamus- Celtic Shield Collection

He has a unique ability to recognize a beautiful object in a piece of wood and uses his skills to reveal the hidden and unique beauty.

He uses Irish native wood grown for decades and dried over many years to create breathtaking and totally unique Urns and memorials.

Seamus has won 20+ Irish National awards for his creations and has been commissioned for unique pieces for the President of Ireland, Royal Dublin Society, Irish Landscape Institute, to name but a few.

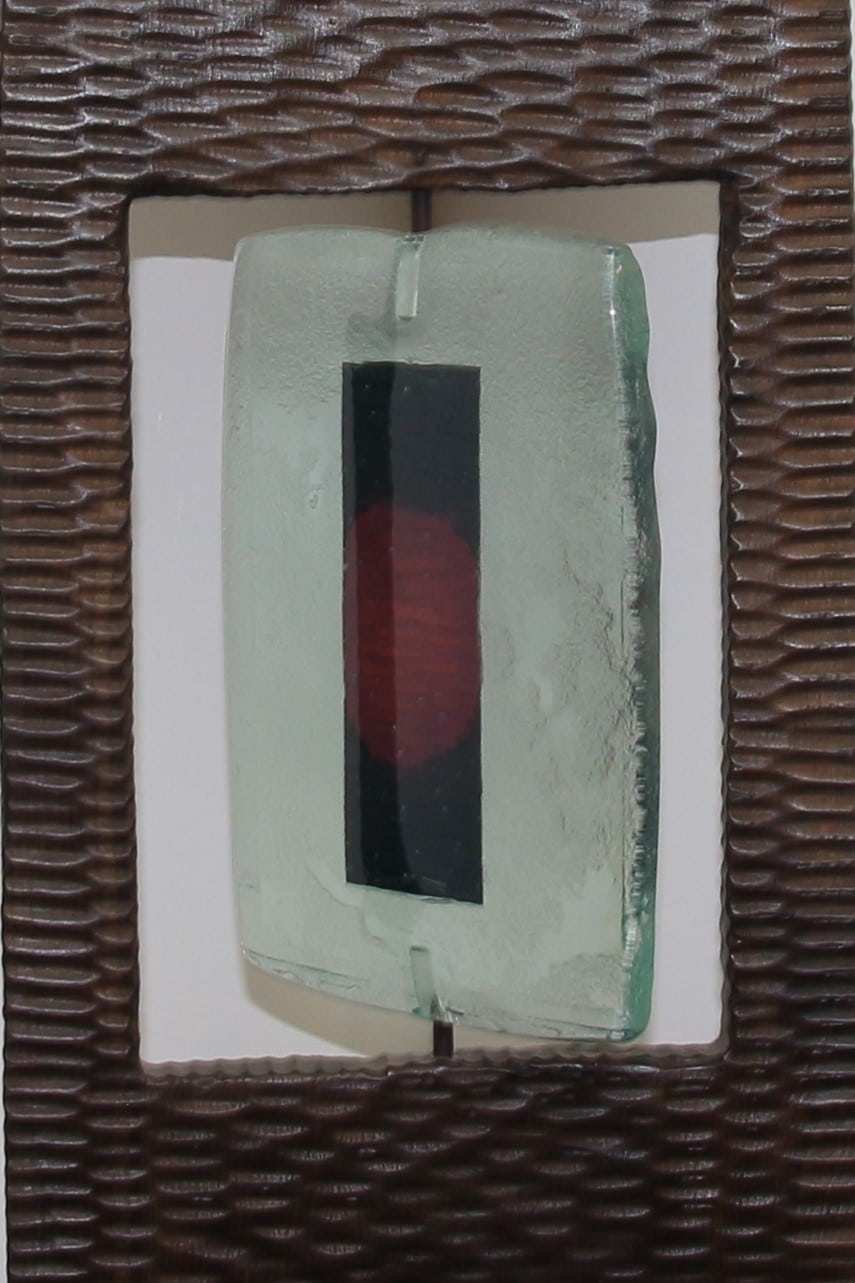

His unique sculptural pieces sometimes use textured, bleached and scorched woods, gold, metals, leather, glass.

Favored techniques include steam bending, texturing, and fine polishing.

His memorial Celtic Shield collection offers families the opportunity to memorialize their loved ones in Art pieces designed to retain the ashes in elegant homes, with a family that is proud of their heritage.

So what is woodturning …Woodturning is the craft of using the wood lathe with hand-held tools to cut a shape that is symmetrical around the axis of rotation. Like the potter’s wheel, the wood lathe is a simple mechanism which can generate a variety of forms. The operator is known as a turner, and the skills needed to use the tools were traditionally known as turnery. In pre-industrial England, these skills were sufficiently difficult to be known as ‘the misterie’ of the turners guild. The skills to use the tools by hand, without a fixed point of contact with the wood, distinguish woodturning and the wood lathe from the machinists lathe, or metal-working lathe.

Techniques.

Complex forms made on a wood lathe develop from surprisingly few types of cuts: parting, planing, bead, cove, and hollowing. Parting separates the wood from the holding device, or establishes depth cuts. Planing is done with a tool in which the bevel below the cutting edge supports wood fibers, just as in a typical wood planer. Beads are a convex shape relative to the cylinder, and coves are a concave shape.

Hollowing techniques are a combination of drilling and scooping out materials. The woodturner is at liberty to choose from a variety of tools for all of these techniques, and the quality of the cuts improves with practice wielding the tool selected. Turners rely upon three points of contact making any type of cut: the tool presses down on the tool rest, and against the woodturner’s body before contacting the surface of the wood, most often with a bevel edge riding the surface of the wood. The objective is to position the tool correctly so that the wood comes around to the cutting edge, generating a thin shaving without chipping or tearing out sections of the wood. Woodturners like Seamus prefer to use very clean cuts to minimize the time spent with abrasives.

The grain in a burr Elm is more dense than ordinary elm heartwood and polishes well.

Seamus- Celtic Shield Collection

The character of the wood creates many challenges for a woodturner like Seamus. As a Turner of hardwoods and Ebony he selects different tools than those used for cutting softwoods. Voids in the wood require higher lathe speeds, fillers, or extra safety precautions. Although other woodworkers value tight, straight grain, woodturners often search out the unusual wood from roots, defects, or diseased portions of trees. The Image on the Left is Burr Elm Urn. Because the grain in a burr is so wild and goes in many different directions it resists splitting and is stable. It is more dense than ordinary elm heartwood and polishes well.